整機(jī)質(zhì)保一年,終身維護(hù),

整機(jī)質(zhì)保一年,終身維護(hù),

定制特殊產(chǎn)品和非標(biāo)自動(dòng)化工作臺(tái)。

數(shù)十道監(jiān)控管理流程。

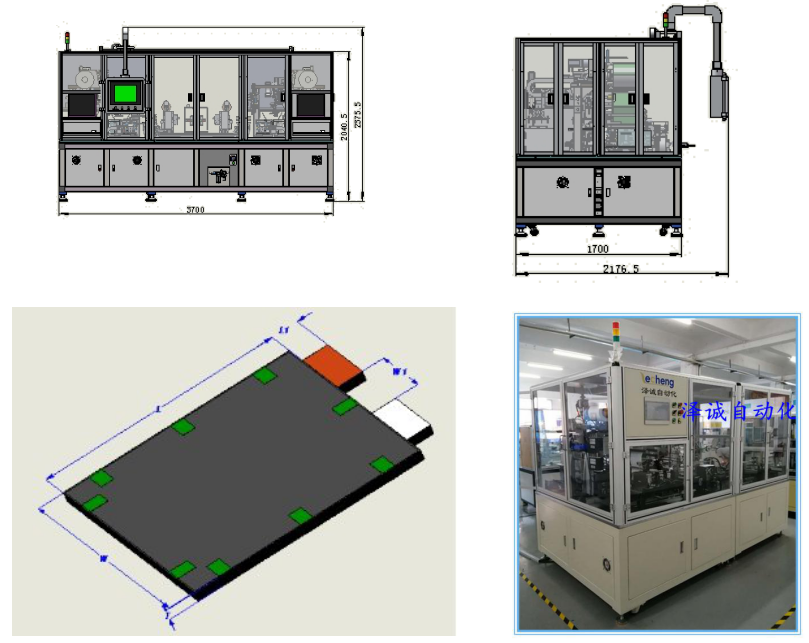

自動(dòng)單工位疊片機(jī)

Automatic simplex laminating machine

1. equipment profile:

1.1 introduction to device functions and principles:

This equipment completes the automatic lamination process of power battery, and its main functions include pole sheet feeding, lamination, tail coil, adhesive and blanking. Diaphragm active unwinding, through the transition roller, the vertical tension mechanism into the main laminating table. The main lamination table drives the diaphragm to move back and forth, folding in a Z shape and placing the pole. Positive and negative manipulator from the positive and negative pole film box to take out the pole film, through the secondary positioning platform positioning, accurately stack on the main lamination platform. After stacking to the set number of pieces, stop laminating, automatic tail coil, edge bag U tape, automatically down to the discharging platform.

2. Equipment functions and technical parameters

Machine specifications project | ZCCE04A-01 | ||

Stacking speed (S/ chip) | 1.2 seconds/piece | ||

Accuracy of alignment between pole and diaphragm | Center deviation ≤±0.5mm (longitudinal) | ||

Diaphragm to diaphragm alignment accuracy | The end alignment deviation is less than ±0.3mm | ||

Single chip alignment accuracy | + / - 0.3 mm | ||

Overall alignment accuracy of poles | + / - 0.5 mm | ||

Auxiliary completion time of a single cell (S) | Single lap tail winding time ≤5s (if winding time is accumulated over many turns), and wrapping time ≤70s | ||

Working time of once installed electrode (h) | 0.5 | ||

Number of laminated | Can be set | ||

Outsourcing the diaphragm | Diaphragm number adjustable | ||

Finishing way | Edge wrap U tape | ||

3.設(shè)備使用環(huán)境

(1)壓縮空氣:0.4~0.8Mpa(4-8kgf/cm2),流量280L/min;

(2)設(shè)備真空要求:真空度:-101kp~-50kp,流量12L/S;

(3)吸塵:乙方設(shè)備中配置排風(fēng)扇,并留出排塵接口;

(4)環(huán)境溫度:20~35℃;

(5)相對(duì)濕度:5~55%HR;

(6)環(huán)境潔凈度:現(xiàn)場(chǎng)無腐蝕性氣體、液體、爆炸性氣體;

(7)電源:AC220V,單相;電壓波動(dòng)小于±10%;電源功率:11KVA。

3. Equipment use environment

(1) compressed air: 0.4 ~ 0.8mpa (4-8kgf/cm2), flow rate: 280L/min;

(2) equipment vacuum requirements: vacuum degree: -101kp ~ -50kp, flow rate: 8L/S;

(3) dust collection: party b shall have an exhaust fan in the equipment and set aside a dust removal interface;

(4) ambient temperature: 20 ~ 35℃;

(5) relative humidity: 5-55% HR;

(6) environmental cleanliness: no corrosive gas, liquid or explosive gas on site;

(7) power supply: AC220V, single-phase; Voltage fluctuation is less than ±10%; Power supply:6KVA.